Assemble a combination space and water heating (combo) system as indicated in building plans. To maintain consistency with Building America’s energy savings goals, this measure guide focuses on the application of a condensing tankless water heater with a hydronic air handling unit (AHU) in single-family homes, but touches on other configuration options.

Install the selected combo system equipment per applicable local and state building codes and manufacturer specifications, and confirm proper operation. Ensure that health and safety measures are in place regarding minimum water temperature and temperature shock, and review proper maintenance and operation requirements with the homeowner.

See the Compliance Tab for related codes and standards requirements, and criteria to meet national programs such as DOE’s Zero Energy Ready Home program, ENERGY STAR Single-Family New Homes, and Indoor airPLUS.

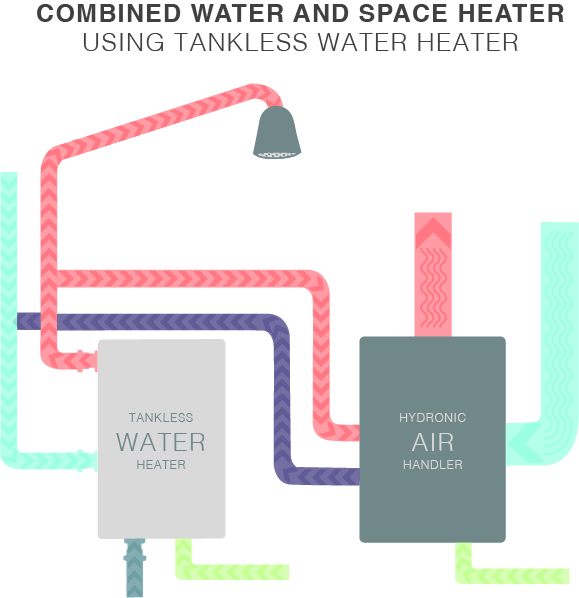

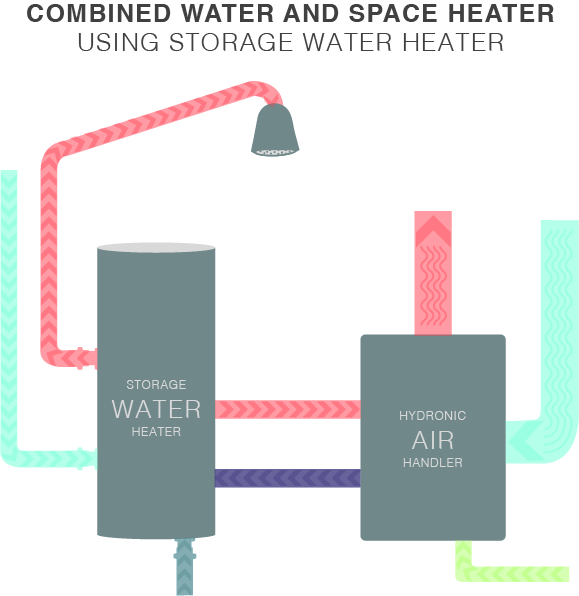

Description DescriptionCombined space and water heating systems use a single thermal engine to provide domestic water heating (DWH) and space heating for a home. The combination of an air handling unit (AHU) and tankless water heater in pre-engineered or engineered applications can enhance the energy efficiency of meeting these heating needs in residential applications.

This measure will focus on the most common forced hot air integrated systems consisting of:

Heated water from the tankless unit passes through a water-to-air heat exchanger to heat the room air. A fan blower circulates the heated air through the heat exchanger and into the home’s air distribution network. If a demand for DHW occurs while there is a call for heat, the system shuts the AHU off until the DHW demand is gone. There are several advantages of this system:

Combined systems, referred to herein as combos, can be purchased as pre-engineered packaged systems or can be custom-built by bringing together AHUs and water heaters built by separate manufacturers. Storage water heaters have historically been used in combo systems, but an influx of foreign tankless (on-demand) water heater technologies that are compact, high-capacity, and wall-hung have encroached the market. Because storage water heaters store hot water, they perform well by quickly delivering water at set point for short demands. However, they deliver varying water temperatures during long draws, because of temperature stratification in the tank. Tankless technology performs well with long draws at steady flow rates. Tankless water heaters in pre-engineered or engineered applications can enhance the energy efficiency of meeting these heating needs in residential applications.

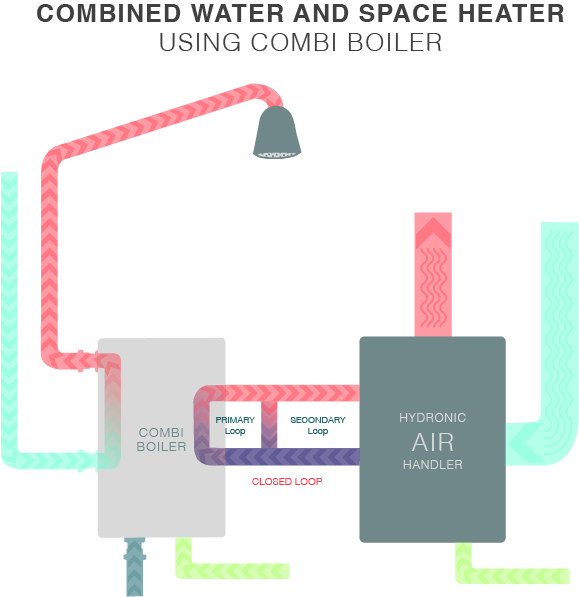

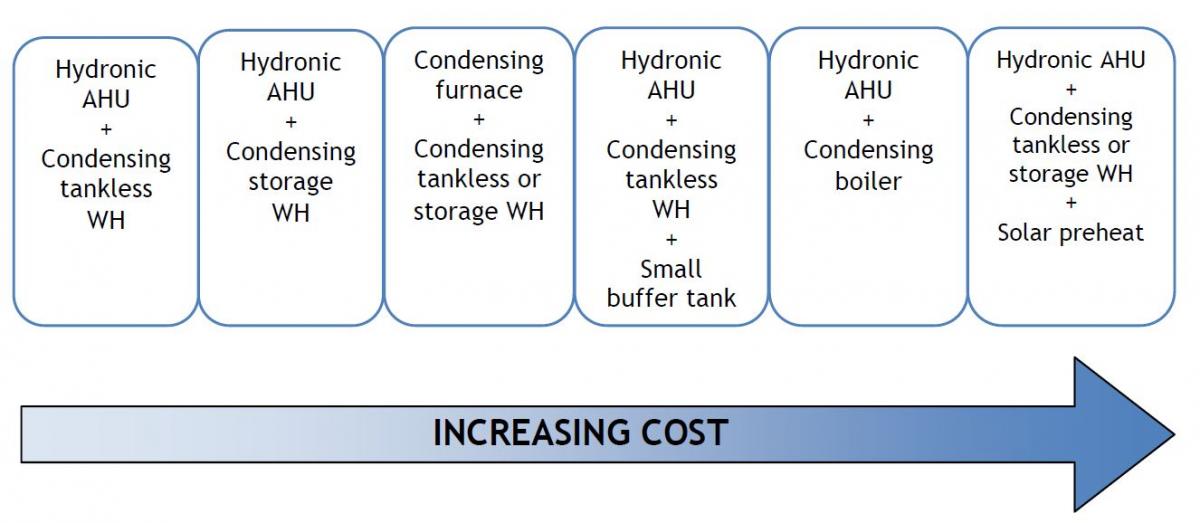

Combination space and water heating systems can be assembled with a range of equipment, such as condensing furnaces or boilers (Figure 2), storage or tankless water heaters (Figure 3), small buffer storage tanks, solar pre-heat, and radiant heating systems. Equipment selection will directly impact the cost of the system as well as the operating efficiency.

Pre-screen potential sites by assessing the residence envelope characteristics, outdoor design temperature, expected hot water usage, and furnace and hot water heater orientations.

Conduct a full assessment of the residence by calculating its heat load using a protocol such as Manual J. Properly size the combo system to meet the estimated space and hot water heating loads of the home by selecting a combination of water heater and AHU that delivers:

Benefits and Costs

Combined space and water heating systems can offer a wide variety of benefits:

These systems do face barriers to wider adoption:

Accord to recent Building America research (Rudd 2012), there are a range of costs for combo systems varying by the equipment included in the configurations. Figure 4 provides a general estimate of those costs. System costs are also strongly influenced by contractor familiarity with the system and installation best practices as well as whether the equipment is being placed in a new construction or retrofit scenario. In retrofit scenarios, there can be additional costs associated with gas line upgrades to accommodate the condensing tankless water heater, duct work (insulation, air-sealing, etc.), and adjustments to piping runs from the existing separate water heater and furnace.

How to Implement a Forced Hot Air Combined Space and Water Heating System

These systems are designed to be professionally installed due to their complexity and the potential need for gas line upgrades (1/2” to 3/4” pipe) to have adequate capacity for the high firing rate of a tankless water heater, and for adjustments to duct work and piping. Combo systems are ideal for new construction applications that minimize duct work and piping runs as well as ensure proper sizing of the gas line, but can be applied in retrofit scenarios as well. The opportunity to properly design and size the system for new construction allows for improved comfort at optimal heating supply air temperatures and flows. There are fewer issues surrounding room temperature recovery after domestic hot water prioritization when ducts are placed within the conditioned space. In retrofit scenarios, it is important that the existing duct system is well-insulated and air-sealed to ensure efficient system performance and there must be the ability for short through-wall or through-roof direct venting.

Installation

Once the home has been determined to be a reasonable fit for a combo system, the contractor can proceed with the installation of the system itself and other ancillary upgrades as required. The installation should ensure domestic hot water (DHW) priority to avoid situations where the AHU would be providing less than 100°F air to heat the home (Rudd 2012). This temperature is too low and can lead to a “cool draft” sensation in homeowners. Delivered air should be in the range of 110°F – 115°F to avoid homeowner comfort concerns. At the same time, the installation should ensure that the water heater is set at the lowest temperature possible to maintain space heating load.

The installation must first be in accordance with the manufacturer’s instructions, and also comply with currently adopted local codes. The following items describe elements of a quality combo system installation.

Combination space and water heating systems can be assembled with a range of equipment, such as condensing furnaces or boilers, storage or tankless water heaters, small buffer storage tanks, solar pre-heat, and radiant heating systems. Equipment selection will directly impact the cost of the system as well as the operating efficiency.

Pre-screen potential technologies by assessing the residence envelope characteristics, outdoor design temperature, expected hot water usage, and furnace and hot water heater orientations.

Conduct a full assessment of the residence by calculating its heat load using a protocol such as Manual J. Properly size the combo system to meet the estimated space and hot water heating loads of the home by selecting a combination of water heater and AHU that delivers:

Combo systems require stable water temperature throughout the range of common flow rates and use patterns. Regular filter cleaning intervals are needed to avoid excessive mineral scale and galvanic corrosion. Consistency of water temperature at low flow rates can be an issue, depending on the minimum draw required to activate the burner (many tankless units have activation thresholds at 0.4 gpm, with some units able to accommodate even lower flow rates once activated). Most manufacturers implement a sensor to detect hot water draws. The sensor shuts the AHU down temporarily to give priority to domestic hot water needs. Room temperature recovery could be significant, depending on the domestic hot water demands, their durations, outside air temperatures, and thermostat cycles.

Health and Safety

A common health and safety concern with combo systems is related to water stagnation in the space heating recirculation loop, which may be unused during the cooling-dominated summer months. The water in this loop will drop in temperature unless regularly circulated with heated water from the condensing tankless unit. Any time temperature in a water heating system drops between 77°F and 122°F (25°C and 50°C), it becomes a potential source for Legionella bacteria (WHO 2011), which can cause an acute respiratory infection in exposed individuals, particularly those with weaker immune systems such as children and the elderly. Some manufacturers have built-in controls to automate circulation and prevent the water temperature from dropping too low. Alternatively, a pump cycling timer could be installed with controls to ensure hot water is circulated for at least 1 minute at least once a week to completely cycle all the water through the hydronic recirculation loop (Rudd 2012).

Durability and Performance

Some manufacturers provide general recommendations to address thermal shock with the installation of a thermal shock dampening manifold installed after the thermostatic mixing valve. The purpose is to defeat cold water “sandwiches” and other low flow related temperature instabilities without introducing excess storage that produces heat loss. Some tankless water heaters are also equipped with an automated and fully modulating bypass for DHW temperature stability to avoid cold and hot water “sandwiches.”

Tankless water heaters have varying low water flow thresholds. Typically there is a general threshold (such as 0.4 gallons per minute) and then a secondary lower threshold that can be maintained once the unit has been activated (such as 0.26 gallons per minute). Low threshold activation is needed to assure availability of hot water at common low flow rates. This is especially important in homes that have installed water conservation devices, such as faucet aerators and other low flow fixtures.

Combo systems require the tankless water heater to supply the air handler unit (AHU) with sufficiently hot water to achieve supply air temperatures of 105°F or higher, which generally requires the tankless unit to produce hot water at 120°F to 160°F. Heating water to this temperature can result in the development of mineral scale and galvanic corrosion, which can require an annual cleaning/maintenance routine to ensure that system performance remains unaffected by build-up. The inlet strainer in a tankless water heater is designed to protect the modulating water valve and flow meter. Potential clogging of the inlet strainer and accumulation of calcium or lime scale in the heat exchanger and piping can be a concern. Additional pre-straining of the water just before it enters the tankless unit is an important step for keeping maintenance intervals as reasonable as possible, generally every year (Rudd 2012). Some manufacturers have built-in controls and indicators that designate when the unit is beginning to lime-up and should be flushed.

There is no formal codes and standards guidance on climate-specific applications of this technology. However, there are considerations that have been noted in past field-based research.

Warmer Climates

The application of combo systems in warmer climates can capture positive energy savings benefits. In warmer climates, the temperature of hot water delivered to the air handler can be turned down from 140°F – 160°F to about 120°F. This lower temperature allows the system to achieve high condensing efficiencies, thereby saving energy and money for the homeowner.

However, warmer climates have smaller overall heat loads that often result in the system operating at less than full-load. Operating at turned down loads negatively impacts the system’s overall efficiency. This issue can be exacerbated in smaller homes with even lower than average heating loads. Currently, commercial systems can accommodate turned down rates of as low as 10% in some cases. Most commercially available condensing tankless systems tend to have large gas input rates (minimum of 150,000 Btu/hr to a maximum of 200,000 Btu/hr). As larger systems, they are more likely to be run at a turned down rate in warmer climates, further restricting opportunities to achieve condensing high efficiencies. Although non-condensing tankless systems are available, they do not offer the energy efficiency benefits of condensing units.

Past research has noted that manufacturers should consider offering smaller systems that would be able to achieve full-load, condensing efficiencies while meeting the more modest heating demands of warmer climates.

Colder Climates

By contrast, the application of condensing tankless combo systems in colder climates can be beneficial since they will often run at full-load. However, the temperature of the hot water delivered to the air handler is often higher (140°F – 160°F) in order to meet the larger heating load. This higher temperature setting makes it more challenging to achieve condensing efficiencies.

Manufacturers have indicated they are working to developing condensing tankless systems can rely on lower temperature hot water to the air handler to boost their efficiency, while still ensuring the water is hot enough to meet health and safety standards.

In cold climates, it is critical to use sealed-combustion, direct-vent, or power-vented equipment. It is also critical to make sure that the air intake and exhaust discharge vents are located sufficiently above anticipated snow line. The intake should be sufficiently separated from the exhaust vent to prevent frost buildup on the cold air intake pipe. The exhaust discharge must be sufficiently high so that frozen condensation that may accumulate on the ground will not block the exhaust pipe. Condensate lines should be directed to an indoor drain.

ComplianceCompliance

The Compliance tab contains both program and code information. Code language is excerpted and summarized below. For exact code language, refer to the applicable code, which may require purchase from the publisher. While we continually update our database, links may have changed since posting. Please contact our webmaster if you find broken links.

As noted in other recent Building America research (Rudd 2012), there is currently a lack of accepted standards or well-vetted guides for best practices of combo system design. Available guidance is generally limited to small-scale, field-based research efforts completed throughout the U.S.

More Info.

Access to some references may require purchase from the publisher. While we continually update our database, links may have changed since posting. Please contact our webmaster if you find broken links.